What are unhealthy coping mechanisms called

The basic unit is an oxy-fuel, semi-automatic coping machine. The operator places the workpiece and finetunes it before starting the cutting. An automated laser option is available to automatically probe the workpiece and adjust the torch height. The basic unit includes powered conveyors that allow the operator to manually measure and mark the length of the feed stock before cutting. Optional automated measuring system using Laser measurement of feed stock is available. Operators can input the material type they wish to cut via the interface. The computer touch screen allows the operator to scroll through a selection of options using pictorial representations. All dimensions of the AISC structural steel are programmed into the computer. The computer displays a fully dimensioned cope drawing, which simplifies programming and minimizes operator error. Operators can modify and override the input, and it can also be saved as a new program, as desired. You can pre-programme the machine from your office using DSTV exported drawings. The operator can use a wireless remote to control the equipment. The Operator can view the equipment from any angle he needs to ensure accuracy and verify operations. The operator marks the material and moves it into position. Finally, hydraulically clamps the material for cutting. The laser is aligned to the operator's mark by the operator and the cycle begins. The torch is ignited, pre-heating material. Operator initiates and finishes the cutting process manually, ensuring that the torch height is maintained.

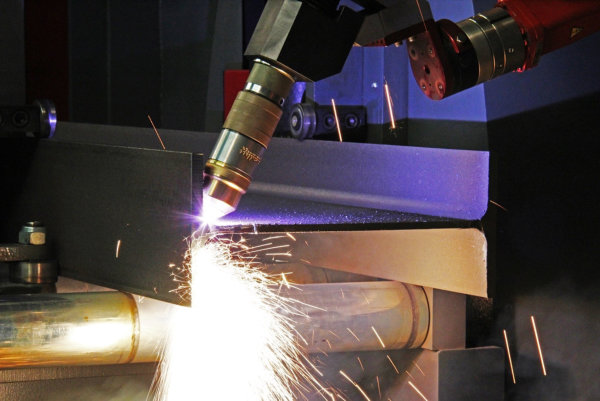

We care about making fabrication tasks efficient and seamless. Our Robotic coping/profile beam can be used to cut angles, channels, square tubes as well as pipes, T Bars and plates. Because it is an efficient tooling platform, our Coping/Profiling Robot offers a multitude of functions for your profiles/pipe cuts. These outputs are H, I andT beams as well as U and/or L channels.